How to remove the dust generated after laser cutting of non-metallic materials?

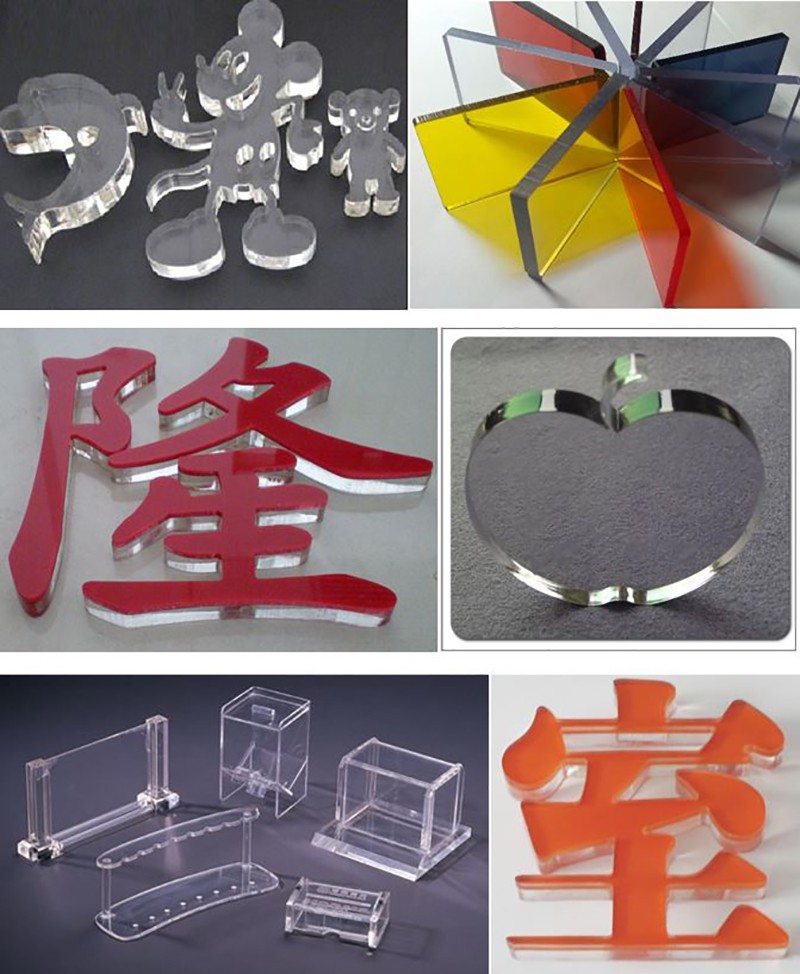

Laser cutting of non-metallic materials is more and more widely used in traditional manufacturing, because of its high efficiency and flexibility, high productivity, fast cutting speed and other advantages. In the processing of many non-metallic plastic products, multi-layer composite materials, etc., laser cutting has achieved an irreplaceable role.

The principle of laser cutting is to use a high-power density laser beam to irradiate the material to be cut, so that the cutting point of the material is instantly heated to the vaporization temperature, and then evaporated to form a processing gap to achieve the purpose of processing. In this process, extremely complex physical and chemical changes have taken place in the deep or surface material of the workpiece being processed. Specifically, the physical change is the generation of dust and particles in vaporized free shapes; the chemical change is the generation of odor, stickiness, oiliness and other substances, depending on the characteristics of the material itself:

There are three main types of laser cutting dust for non-metallic materials:

1. The dust generated by laser cutting of non-metallic materials is a physical change, and professional laser dust removal devices can be used to remove dust, such as needle-punched felt film-coated filter bags, film-coated filters, etc., which can basically achieve more than 90% of the dust filtration. and purification;

2. The odor, stickiness and oiliness produced by laser cutting of non-metallic materials belong to the category of dust that is more difficult to handle. Because oily and sticky substances are very easy to block the filter. Therefore, activated carbon adsorption purification and other methods are usually used to deal with the peculiar smell produced by high temperature scorching and melting to achieve the purification effect;

3. If the non-metallic material laser cutting dust has a mixture of physical properties and chemical properties at the same time, that is, the dust is particles containing peculiar smell and stickiness, which requires the purification equipment to have both dust purification ability and odor purification ability. This requires manufacturers to estimate and judge the nature of the dust in advance in order to choose the correct purification device.

Design and functional requirements of non-metallic material laser cutting dust treatment purifier:

1. For dust treatment, the fume purification equipment must have high-efficiency filtration function, and must have strong oil resistance and anti-stickiness;

2. For the treatment of odor dust, the laser dust removal equipment must have the adsorption function of activated carbon, so as to ensure that the odor dust can be effectively treated;

3. Considering that dust may also show complex changes due to factors such as different materials, density, temperature, space characteristics, etc., it is required to reserve a process design for additional accessories when installing dust removal equipment.

Recommended laser cutting machine for non-metallic materials:

Technical advantages:

01. Reinforced welding bed, large gantry precision milling, annealed and vibration aging to eliminate stress, deformation tolerance within ±0.02mm;

02. The beam structure is made of high-strength aluminum alloy, which has the advantages of light weight, less resonance and smoother operation than the traditional steel frame beam;

03. Very suitable for the whole sheet cutting of MDF, acrylic and other materials.

04. The full gear rack motion structure not only realizes the high-precision cutting of the plate, but also effectively ensures the stability of the equipment during high-speed operation.